IG-01 Argon gas fire extinguishing systems are inert gas extinguishers defined in TS EN 14005, ISO 14520 and NFPA 2001 standards. It is used in large volumes such as archives, museums, libraries and warehouses. It is used in its pure form as a chemically non-conducting extinguishing gas. Therefore, during the filling, the mixture completely eliminates the risk of filling different amounts of gases. Argon gas is stored in 200 bar and 300 bar cylinders. With a single cylinder group, more than one space can be protected with selector valves.

The extinguishing principle is based on the principle of reducing combustion by reducing the oxygen concentration in the application area to 15%. The system is designed with a hydraulic calculation programe approved by VDS. It is desired to reach the extinguishing concentration in a maximum of 60 seconds. This means that we can increase the distance between the cylinder placement and the nozzle. By using a low pressure pressure switch for each cylinder, the amount of gas in the cylinders can be continuously monitored. All products used in the system comply with TS ISO 14520 – TS EN 15004. All cylinders are CE marked and ∏ marked according to PED and TPED directives.

The amount of relief damper to be used depending on the material properties of walls, doors and similar structural elements should be determined according to the hydraulic calculation results in the places where argon application is performed.

The basic design of the valves does not allow small leaks that may occur as a result of accidents to drain the entire system. This feature allows all gas in the cylinder to be tested without draining when the system is connected to the installation or after filling.

Usage Areas

Archives, museums, laboratories, subway stations, areas where valuable works are kept, electrical panel rooms, low voltage rooms, medium voltage rooms, monitoring and monitoring rooms and similar places.

Main Features

- ARGON exists naturally in the atmosphere

- Can be designed according to ISO 14520 – TS EN 15004, NFPA 2001 and CEA 4008

- Can be used in person places

- Provides economic solution advantage with large volumes of selective valves

- Cheap and easy to refill

- No electrically conductive

- Does not require cleaning after gas discharge

- No chemical decomposition product after quenching

- Does not leave toxic substances after application

- Does not cause loss of vision and harm to people during application

- According to EPA data, ozone is harmless and does not cause greenhouse effect

- It is colorless, odorless and tasteless.

- Argon has no chemical etching properties. It is therefore extremely easy to store and store.

- Provides visibility in the space during gas discharge. Therefore, it allows the view of the exits and escape routes thanks to the visibility that it provides even during gas discharge in manned spaces.

- IG-01 80 and 140 lt capacity cylinders in the form of gas, 150, 200 or 300 bar is stored under pressure. For the same space, it is necessary to use less cylinders with 300 bar system. Therefore, the system requires less space.

Physical Properties

- Chemical Name Argon

- Chemical Formula Ar

- Nomenclature IG-01 according to ISO 14520 – TS EN 15004 and NFPA2001

- Molecular Weight 39.9

- Boiling Point -185,90 ° C at 1,013 bar

- Critical Temperature -122,30 ° C

- Critical Pressure 49 bar

- Maximum Filling Pressure 200/300 bar

- Design Concentration for Heptane 51%

- Overflow Factor for Heptane at 20 ° C 0,701 m3 / m3

- Design Concentration for Hazard Class A (ISO) fires 41.9%

- Flow Coefficient for Hazard Class A (ISO) fires 0,534 m3 / m3

- Design Concentration for High Hazard Class A (ISO) fires 48,4%

- Flow Coefficient for High Hazard Class A (ISO) fires 0,650 m3 / m3

- Design Concentration for Class A (NFPA) fires 38.7%

- Flow Coefficient for Class A (NFPA) fires 0.481 m3 / m3

- NOAEL 43%

- LOAEL 52%

- Ozone Damage Potential 0

- Greenhouse Effect Potential 0

NYTRARGON® is a clean gas quenching gas, defined as IG-55 in NFPA 2001, consisting of 50% Argon and 50% Nitrogen.

Advantages of NYTRARGON® System

- It does not leave residue and does not require cleaning.

- It has no negative effects on human health.

- The maintenance cost of the system is low.

- No electrical conductivity.

- It does not harm the ozone layer and does not cause global warming.

- The system rollers can be located in areas far from the protected area.

Typical Applications of the NYTRARGON® System

- Computer rooms

- Archives

- Museums

- Telecommunication centers

- Laboratories

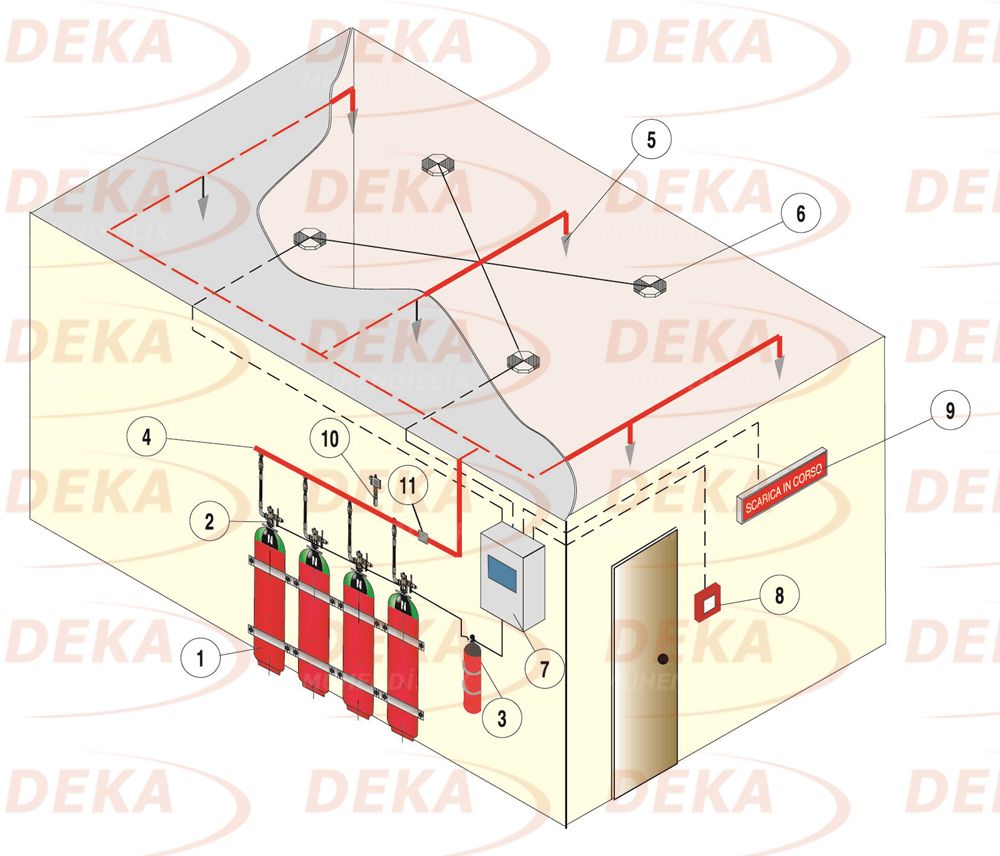

The NYTRARGON® System consists of the following components

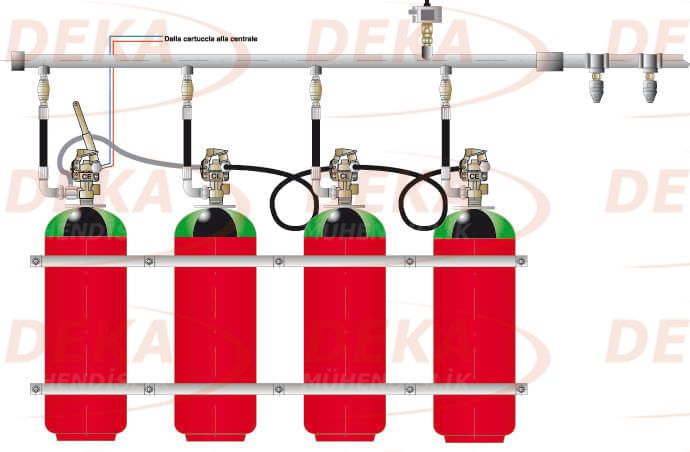

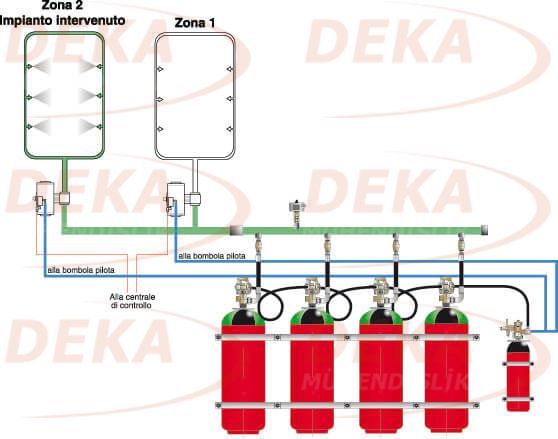

1) NYTRARGON® Tubes

2) Solenoid Valve

3) Pusher Cartridge

4) Collector

5) Nozzles

6) Detectors

7) Fire Alarm Panel

8) Manual Unload Button

9) Audio / Visual Alarm

10) Pressure Switch

11) Orifice