In-panel fire extinguishing systems are extinguishing systems that we cannot provide total volume protection, but we use in areas that are closed volumes or which can be accepted as closed volumes.

Fire hazard; Used to protect the interior of critical enclosures, storage compartments, machinery and vehicles. We protect the enclosed volumes that we want to protect because they are valuable, with the least damage in the fire and which we want to be available immediately after the fire is extinguished, with in-panel extinguishing systems.

Extinguishers used in the panel extinguishing system:

- FM-200 (HFC 227ea)

- Novec 1230 (FK-5-1-12)

- Carbon dioxide (CO2)

- Foam

- Dry Chemical (ABC, BC, D)

In-panel extinguishing system advantages

- It does not need any power supply

- Not affected by energy cuts

- It is a completely self-contained system

- No need for expensive control panels and / or automatic fire detection systems

- Simple design

- Easy to apply

- Reliable detection hose prevents incorrect system discharges and costs

- It is easy to reach the hard-to-reach points where the detection methods cannot be used with the flexible detection hose.

In direct panel extinguishing systems, it acts as both sensing and discharge line for heat-sensitive hormone. In the indirect system, it acts as sensing heat sensitive hormone, and pipes and nozzles discharge line.

Usage Areas

- CNC machines

- PNC machines

- Closed milling machines

- Robotic welding machines

- Plastic Injection Mold Machines

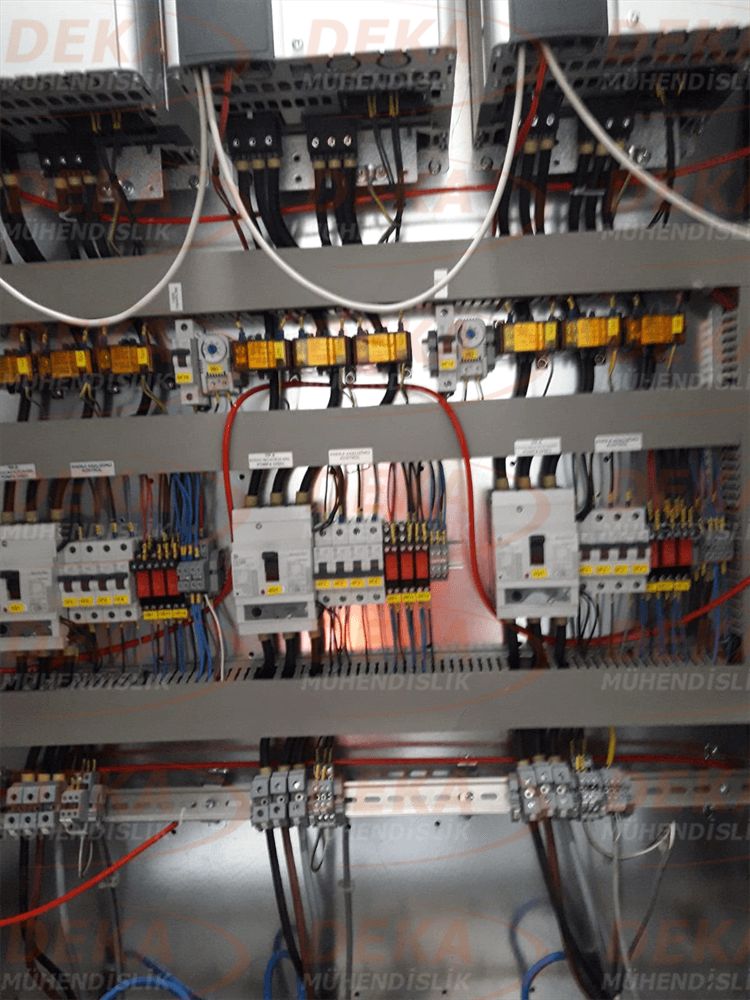

- Electric control cabinets

- Electric panels

- Computer cabinets

- Transformer cabinets

- Generator booths

- Automation and control panels

- Critical data warehouse boards

- UPS boards

- In wind energy stands

- Medical equipments

- Industrial equipment

- forklifts

- Mining industry

- Harvesting machines and motors

- Paper, dough machines

- Agricultural equipment

- Research and development laboratories

- Chemical product laboratories

- Pharmaceutical laboratories

- University and school laboratories

- Public transport and private vehicles