Carbondioxide is an electrically nonconductive, odorless, colorless fire extinguishing agent, which is 1,5 times heavier than air. CO2 leaves no residues after vaporization, and suppresses B and C types of fires by reducing the oxygen content in air within protected areas. CO2 is not a toxic gas; however it is not a preferred fire extinguishing agent in areas where people exist, since it reduces the oxygen content in the air once discharged in high densities. For example, a blocking valve should be placed in the installation. After making sure that there are no people in the place, the blocking valve should be opened. After the application, it should be ensured that the space is ventilated. Carbon dioxide gas resets the viewing distance, so someone in the application area cannot escape. The carbon dioxide gas has high cooling properties and reduces the oxygen level required for inhalation to below 15% and can lead to fatal results.

The CO2 gas used in carbon dioxide fire suppression systems reduces the oxygen content in the air under 15% to prevent and extinguish fires by absorbing the heat.

Advantages of the carbon dioxide system:

- It does not harm ozone.

- Refill costs are low.

- Local or total volume extinguishing system applications can be made.

- Does not require cleaning after gas discharge.

- Does not transmit electricity.

- It is very successful in deep fires.

Typical Areas of Application:

- Power transfer rooms

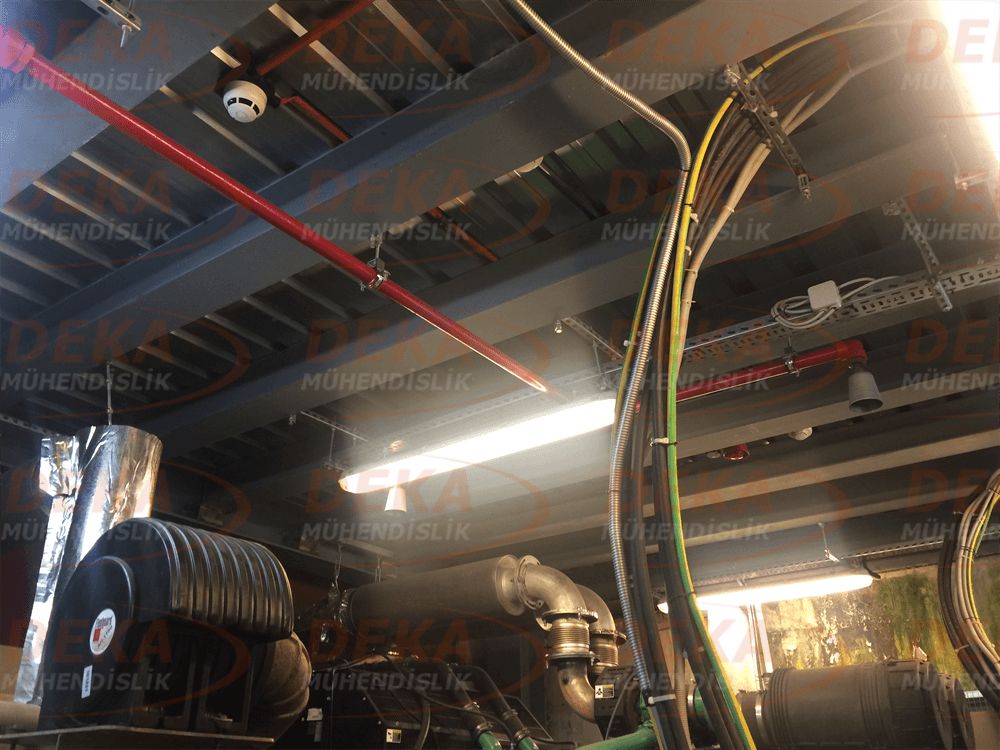

- Generator rooms

- Engine compartments

- Record rooms

- Archives

- Printing offices

- Industrial ovens

- Computer rooms

- Electrical rooms

- Flammable liquid storage rooms

- Paint cabinets

Carbondioxide systems are generally divided into two categories: High and Low Pressure systems.

Low Pressure Systems: Low pressure carbondioxide systems are used for total flooding applications where high amounts of carbon dioxide and large CO2 cylinders are required.

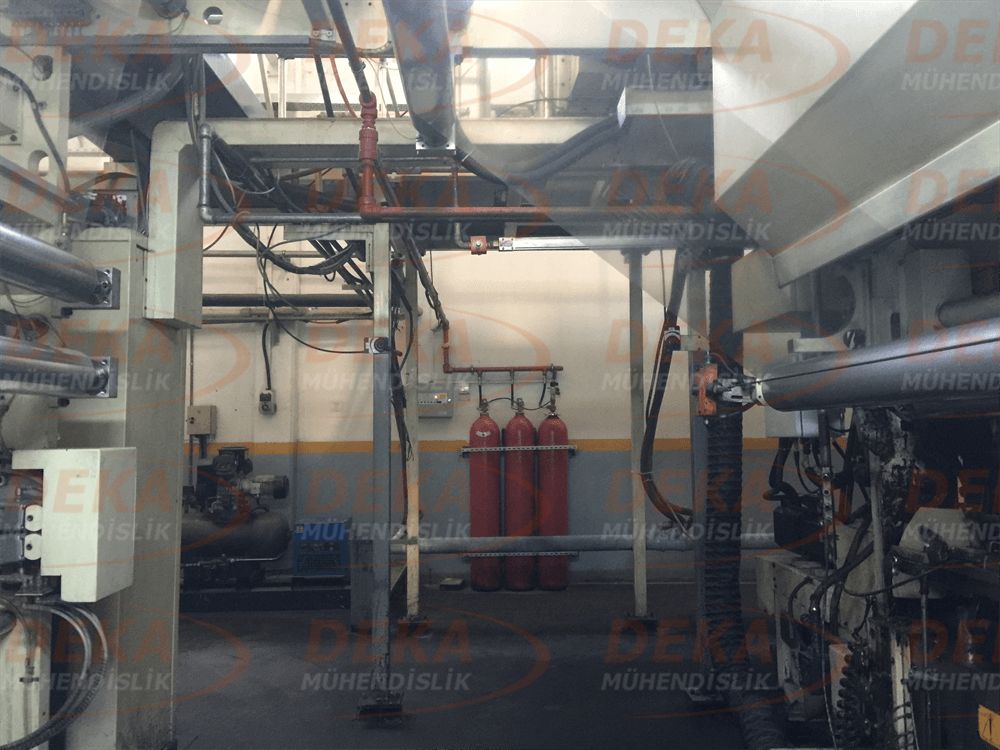

High Pressure Systems: High pressure systems are used both for total flooding and for local applications.

CO2 is a naturally high pressure gas. It switches between liquid and gas states depending on the ambient temperature. Therefore, it is not possible to check the cylinder pressures using manometers. It is required to check the status of cylinders from the fire alarm system or the weights of cylinders can be monitored through a weighing mechanism.

Use and Restrictions: Due to its suppression principle, CO2 gaseous fire suppression systems are inefficient and cannot be used for suppression of fires involving reactive metals such as Sodium, Potassium, Magnesium, Titanium, Zirconium, Uranium, Plutonium, as well as the metal hydrates, some peroxides, white phosphor and cellulose nitrate, and other pyrophoric substances such as gunpowder, which can burn without oxygen.

Weighing Mechanism: Each cylinder is hung on a profile frame complete with a weighing mechanism. In case of loss of gas, cylinders rise due to the counterweights of the weighing mechanism. The system also generates warning signal by means of a micro-switch.

1 – CO2 cylinder 67lt – 45 Kg

2 – Rapid discharge valve 1”

3a – Selenoid actuator

3b – Pneumatic actuator

3c – Selenoid + pneumatic actuator

4 – Vent Valve

5 – Hose between cylinder

6 – Hose pilot cylinder

7 – Duck bend ¾”

8 – Non return valve

9 – CO2 pressure switch

10 – Manifold

11 – CO2 bell

12 – CO2 discharge horn

13 – Wall brackets

14 – Interconntector pilot cylinder