Fire cabinets system is one of the fixed pipe water firefighting systems applications. It is used to allow people inside the building to control and extinguish a small fire nearby. It can be mounted on walls or in cabinets.

Fire cabinet systems with high buildings and a total indoor usage area of more than 1000 m2 in workshops, workshops, warehouses, accommodation, health, assembly and education buildings, indoor car parks with a total area of more than 600 m2 and a thermal capacity of over 350 kW It is compulsory to be done in their apartments.

Fire cabinets are placed on each floor and in each section separated by fire walls, the distance between them is not more than 30 m. Fire cabinets are placed as close as possible to the corridor exit and stairway, which is used as an emergency escape route as much as possible. In case the building is protected by a sprinkler system and firefighting water inlets are left on the floors, fire cabinets can be fed from the wet type sprinkler branch line and the distance between them can be increased up to 45 m.

The cabinet and cabinets where the hoses are stored must be large enough to allow the necessary devices to be laid. In structures without trained personnel with skills such as laying and connecting hoses or firefighters, round semi-rigid hose fire cabinets must comply with TS EN 671-1. The hose must be round semi-rigid TS EN 694 norm, 25 mm in diameter, its length does not exceed 30 m, and it must be able to close nozzles, spraying or sprinkling or all three.

The design flow rate of 100 l / min and the design pressure should be 400 kPa in fire cabinets with round semi-rigid hoses without fire-fighting water intake. If the pressure at the nozzle entrance exceeds 900 kPa, pressure reducers should be used.

Flat hose fire cabinets that can be used in buildings that have to have a trained fire extinguisher must comply with TS EN 671-2 standard. The flat hose; It is imperative that the nominal diameter does not exceed 50 mm, its length does not exceed 20 m, and it is capable of closing nozzles, spraying or sprinkling or all three. Cabinet design flow should be 400 l / min and design pressure should be at least 400 kPa. If the pressure at the entrance to the nozzle exceeds 900 kPa, a pressure reducer should be used.

Periodic maintenance of fire cabinets and hose reel systems in buildings specified in TS EN 671-3 standard is mandatory to be done at least once a year by the owner, manager or responsible building authority.

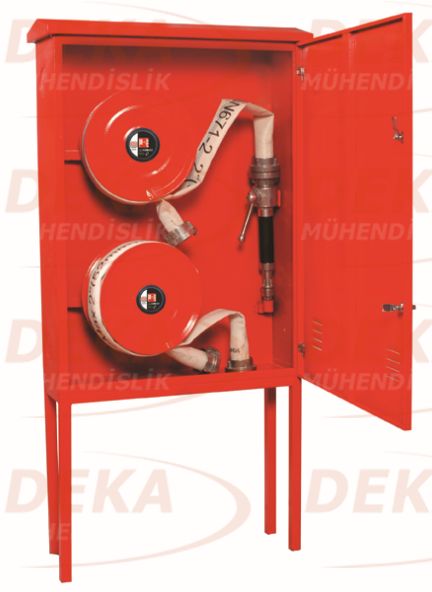

On and in wall mounted, tube partitioned, foamable type, models suitable for the desired color and decoration, a metal cover or tempered glass fire cabinets are the models used in indoor fire cabinet applications.

These are models that are used in buildings and outdoor fire cabinet applications where there are footed, roofed, surface mounted, on the Wall mounted, tube partitioned, double rolled, foamable type, with a metal cover or tempered glass suitable for the desired color and decoration.